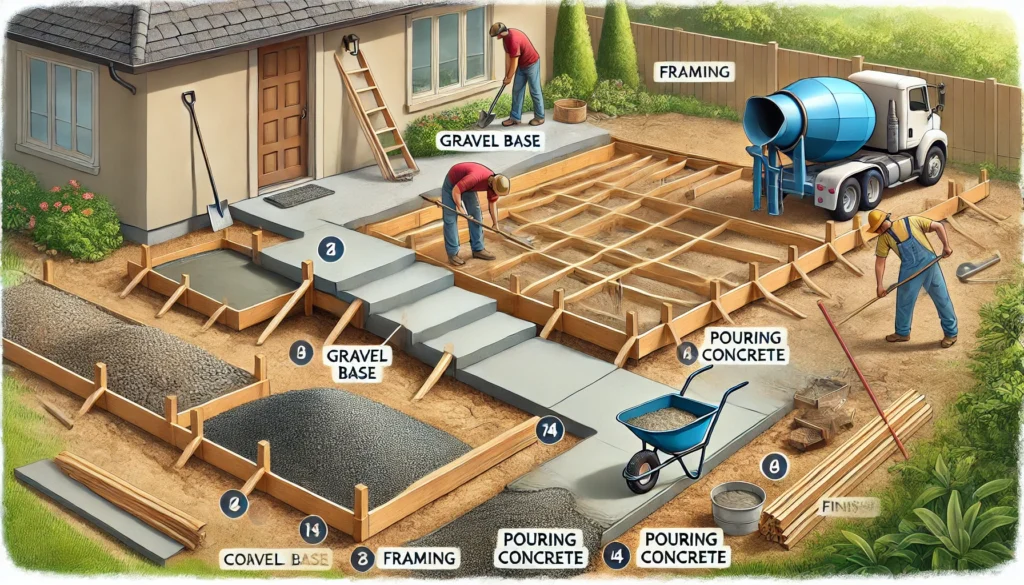

How to Install Durable Driveways and Sidewalks: Best Practices for Long-Term Performance

Learn the best practices for installing durable driveways and sidewalks, from material selection to subgrade preparation and expansion joints.

How to Install Durable Driveways and Sidewalks: Best Practices for Long-Term Performance Read More »

Concrete, Concrete Services, Paving