Homeowners are increasingly looking for ways to build smarter—not just in design, but in environmental impact and cost-efficiency. That’s exactly where 3D printing steps in. This innovative technology is changing the game for concrete construction, cutting down on material waste and reducing overall expenses. With sustainability becoming more than just a buzzword, understanding how 3D printing fits into your home construction plans could be a future-proof move. Let’s explore how it works and why it’s sparking change across the industry.

3D Printing Meets Concrete Construction: Why It Matters to Homeowners

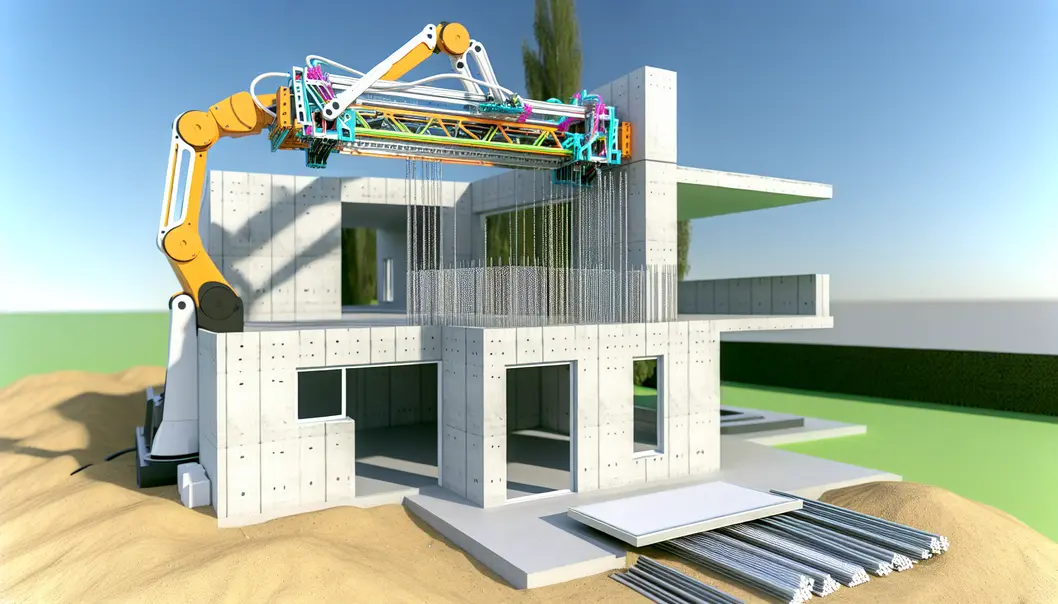

Picture a giant robotic arm, guided by computer software, moving with precision and layering concrete like frosting on a cake. That’s essentially how 3D printing works in home construction. Rather than pouring concrete into wooden molds or using traditional bricklaying techniques, builders now use automated machines to create walls and structural elements by printing them layer by layer. It’s fast, efficient, and increasingly reliable.

This method—called additive manufacturing—reimagines how homes are built. For homeowners, one of the most noticeable impacts is time. Traditional construction can stretch out for months due to factors like weather delays, crew availability, and material delivery issues. 3D concrete printing streamlines the process dramatically. Homes that might take 4-6 months to build conventionally can be completed in a matter of weeks. The controlled environment and automation reduce unexpected delays and help projects stay on schedule.

Another major benefit is waste reduction. Instead of cutting and shaping materials on-site, which produces leftovers and debris, 3D printing uses only the amount of concrete required for each layer. There’s no need for temporary forms or excess trimming. This not only minimizes landfill contributions but also helps homeowners avoid additional waste disposal costs.

Then there’s the design advantage. Curved walls, rounded edges, and complex architectures previously considered too costly—or outright impractical—can now be realized with surprising ease. Because the printer follows a digital blueprint, it can reproduce intricate designs repeatedly without increasing build time or costs. Homeowners no longer have to choose between creativity and affordability. Customization becomes accessible, not extravagant.

Real-world examples are increasingly common. Across the U.S., homes built using 3D-printed concrete are popping up in both rural and urban settings. Some developers are even creating entire communities based on this technology, aiming to address housing shortages affordably and sustainably. In Texas, a state known for its expansive growth and housing innovation, several concrete homes have been completed using robotic printing. These homes meet standard building codes and offer the durability expected in concrete structures—resistance to pest infestation, moisture damage, and extreme weather.

For homeowners wondering about the durability or maintenance needs of 3D-printed concrete homes, the good news is that the material is just as robust as traditional poured concrete—sometimes even stronger. It’s also versatile. Once a structure is printed, contractors can apply finishes, install insulation, and complete interiors much like they would in traditional builds. Features such as polished concrete floors or custom patios can be added post-construction. For readers interested in enhancing their concrete spaces, projects like concrete resurfacing for patios remain entirely compatible with 3D-printed materials.

As this technology continues to grow, it isn’t just changing how homes are built—it’s redefining the homeowner experience. Shorter build times, lower material waste, and expanded creative freedom mean the home-building process is more aligned with modern values: efficiency, sustainability, and personalization. Instead of a stressful, drawn-out construction phase, homeowners can look forward to moving into a tailor-made, eco-conscious space faster than ever before.

Less Waste, More Savings: The Environmental and Financial Benefits

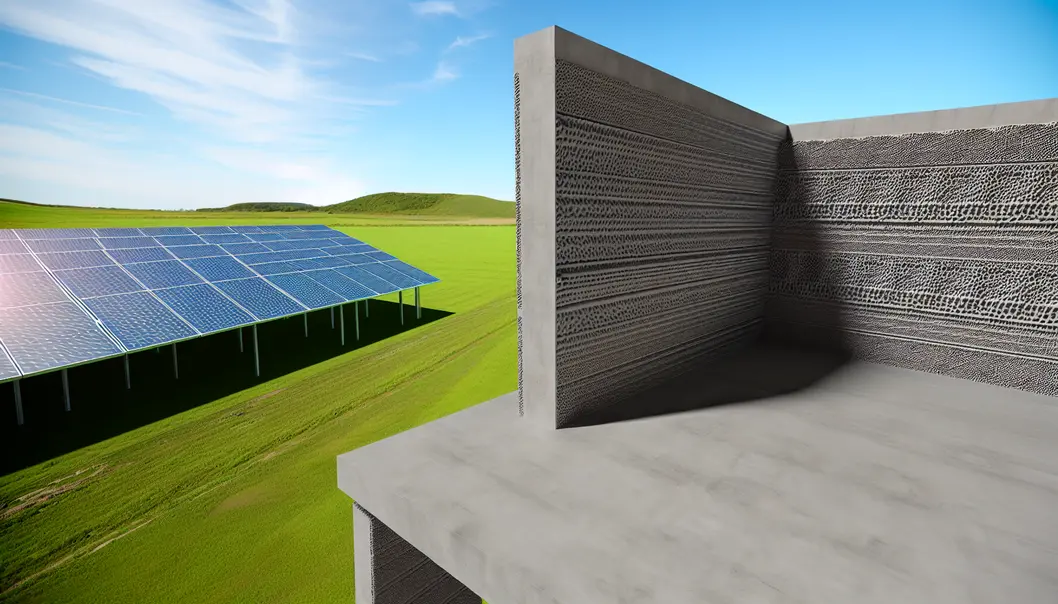

Traditional concrete construction can be wasteful. Materials are over-ordered to avoid shortages, formwork is often discarded, and excess concrete winds up in landfills. With 3D printing, these wasteful habits are drastically minimized. The printer precisely extrudes only the amount of concrete needed for each layer, reducing the over-pouring common in manual pours. This controlled deposition limits spillage and eliminates the need for bulky disposable molds.

Waste reduction has direct consequences for both the environment and your wallet. Less wasted material means fewer raw resources pulled from quarries and less energy used in transporting and mixing concrete. It also reduces the climate impact caused by excess cement production, a process known for releasing significant carbon dioxide. For homeowners, this level of efficiency often leads to lower overall material costs and fewer fees related to cleanup or disposal of construction debris.

Labor presents another major opportunity for savings. Conventional concrete work requires large teams to handle setup, pouring, and finishing. That includes building wooden forms, placing rebar, and waiting between pours. It’s time-intensive and labor-heavy. 3D printing replaces many of these tasks with a mechanical process handled by a smaller crew. Fewer personnel means reduced labor costs and insurance liabilities for contractors—savings that are increasingly passed on to the homeowner.

Because the printing process follows a digital blueprint down to the millimeter, the need for expensive rework is also diminished. Walls are printed exactly where intended, with openings and utilities integrated into the design. There’s no need to cut into walls for last-minute changes, overpour damaged sections, or redo forms that didn’t hold. These micro-level efficiencies compound into significant cost savings and reduce both delays and frustration.

From a sustainability perspective, 3D printing in concrete construction doesn’t just reduce waste—it redefines how efficiently we use resources. Imagine building a home with a tool that measures every pour with computer accuracy, ensuring nothing extra is used unnecessarily. This isn’t just a theoretical benefit; it’s become reality on job sites around the world. That level of precision makes the construction process much cleaner in every sense of the word.

Homeowners considering new construction or expanding onto their home should consider these long-term benefits. Not only are upfront costs potentially lower due to reduced labor and materials, but the speed and accuracy of the process cut the need for ongoing corrections or structural issues down the line. Over time, the sturdiness and low-maintenance nature of printed concrete structures mean fewer repair bills and longer lifespans for walls and foundations.

For those curious about how material waste affects traditional projects, or what options are available for managing excess or cracking after install, this guide to driveway repair in Houston offers useful insight. While it focuses on driveways, many of the same concerns apply to walls, patios, and foundations formed with outdated construction practices.

The less material you waste and the less labor you need, the more savings make it back into your pocket. With 3D printing, that’s not a vague promise—it’s measurable progress in homebuilding.

Final words

As demand grows for smarter, greener, and more affordable building methods, 3D printing in concrete construction is leading the charge. For homeowners, it means quicker project completion, less wasted material, and long-term cost savings—all while being kinder to the environment. With the technology rapidly advancing, this method is no longer futuristic—it’s becoming an accessible reality. Keeping sustainability at the heart of your home’s foundation isn’t just good for the planet; it’s good for your budget too.

Ready to build smarter? Contact Cross Construction Services today for quality concrete construction backed by decades of experience.

Learn more: https://ccsconcretedriveways.com/#quote

About us

At Cross Construction Services, we specialize in creating durable, aesthetically pleasing driveways that not only enhance the curb appeal of your home but also add significant value to your property. With over three decades of experience in the construction industry, our team in Houston, Texas, is committed to delivering top-quality craftsmanship and unparalleled customer service.