Sustainability is no longer a buzzword—it’s a must-have in home improvement, and concrete construction is no exception. Whether you’re laying a new driveway or building a patio, the materials you choose matter. Thanks to recent advances in artificial intelligence, concrete is getting a much-needed eco-upgrade. From reducing waste to optimizing mix design, AI is helping homeowners get stronger concrete that’s also kinder to the environment.

AI Takes the Guesswork Out of Concrete Mixes

For decades, creating the ideal concrete mix has required a mix of knowledge, guesswork, and repeated trials. Contractors would manually balance strength, cost, curing speed, and environmental conditions by intuition or prior experience. That often meant overcompensating—typically by adding more cement than necessary to guarantee durability. But cement production is one of the largest contributors to carbon dioxide emissions. Every extra pound not only raises your project’s cost but also impacts the planet.

Artificial intelligence is changing this approach at its core. Instead of making approximations, AI analyzes enormous amounts of data to fine-tune concrete recipes from the ground up. These systems incorporate variables such as regional climate trends, ongoing weather, soil composition, past project outcomes, transportation time, and environmental regulations. Advanced predictive algorithms can then simulate how different ratios will perform under your home’s unique conditions—whether it’s a shaded backyard patio in Sugar Land or a sunbaked driveway in Houston.

This tailored approach has clear benefits. By right-sizing the mix, AI systems can reduce the amount of cement used without sacrificing long-term strength or durability. That’s not only more sustainable—it leads to lower material costs and a lighter carbon footprint. A driveway designed with optimized AI mixes may contain fly ash or slag as partial cement replacements, intelligently balancing curing time with structural integrity. These mixes aren’t generic; they’re designed for your site’s specific stress demands, moisture exposure, and seasonal temperature highs and lows.

Beyond composition, AI also helps ensure consistency. Traditional on-site batch mixing sometimes resulted in variable quality depending on the crew or conditions of the day. Now, digital platforms powered by AI can communicate directly with mixing equipment, ensuring the proportions are not just accurate but adapt in real time to evolving job site factors. For example, if the humidity changes rapidly in the middle of a pour, the system can recommend mix adjustments mid-process.

For homeowners, this means confidence that your new concrete surface is engineered to last the environment it’s installed in—whether it faces intense UV exposure or frequent freeze-thaw cycles. And because AI-optimized mixes avoid overbuilding, they can help prevent issues like premature cracking, discoloration, or scaling that sometimes plague over-rich mixes. If you’re planning a project in Houston and want to understand how this could affect your bottom line, our guide to the costs of a concrete driveway breaks down the key pricing factors.

As we move deeper into smarter construction, solutions like AI-driven mixing aren’t just cutting waste—they’re enabling greener, longer-lasting, and more cost-effective projects. The concrete you pour becomes not just a surface but a custom-engineered product shaped by data and purpose. And once it’s placed, the next breakthrough—AI-powered curing oversight—ensures that early precision is carried through to long-term performance.

Smart Monitoring for Long-Lasting Concrete

Once a concrete slab is poured, the curing process becomes a critical phase that determines long-term durability. Traditional methods rely heavily on predetermined timelines, site experience, and weather guesswork. But curing concrete is as much about precision as it is about patience. The wrong exposure to heat, wind, or water loss at the wrong time can lead to cracking, scaling, or premature wear—especially in home projects like sidewalks, patios, and driveways. Fortunately, artificial intelligence is replacing guesswork with exactitude.

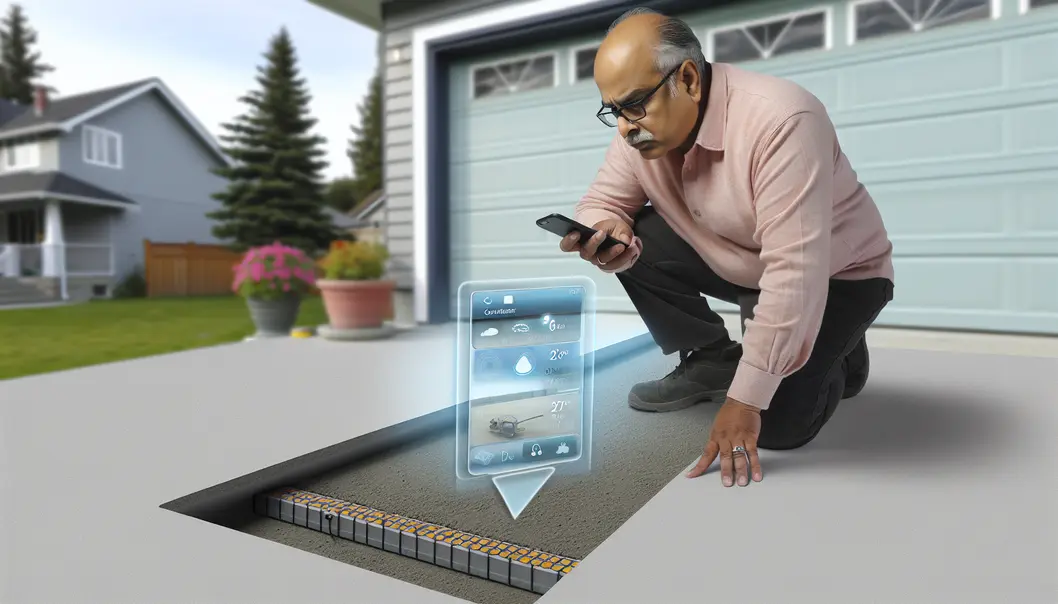

Embedded AI sensors can now be placed directly within the concrete slab to track real-time curing conditions. These slender devices detect and report metrics like internal temperature, humidity, and curing progress. Unlike visual checks or static schedules, sensors provide continuous, data-driven updates. Contractors no longer have to wait for signs of cracks or failures—they’re alerted to potential problems before they happen. If moisture levels drop too quickly, for example, an automatic notification can recommend misting or covering the slab to retain hydration. Similarly, if the internal temperature gets too high or low, curing procedures can be modified to maintain optimal strength development.

This kind of responsive, AI-integrated oversight translates directly into longer-lasting surfaces. A driveway or patio cured consistently and correctly won’t just survive weather changes—it maintains its compressive integrity for decades. For homeowners, that means fewer repair bills and greater peace of mind. Moreover, by preventing common issues like premature drying or uneven strength distribution, AI monitoring reduces material waste and environmental impact.

Real-time curing management is particularly useful in climates like Houston’s, where rapid weather shifts can complicate even well-planned installations. Contractors in such regions now have the tools to adapt in the moment, rather than overcompensate with excessive materials or unnecessary delays. Homeowners wondering how weather fluctuations affect their driveway installation can learn more about these impacts in this guide to driveway repair in Houston.

While the idea of embedding smart sensors might sound futuristic, the technology is being adopted rapidly across the residential concrete sector. It’s not just for skyscrapers and bridges anymore. For any home project involving concrete—whether it’s a new walkway or a resurfaced patio—intelligent curing tools now ensure the material performs as well as it was designed to. That performance is no longer left to chance or schedule-based routines. Instead, every step is guided by actual conditions inside the mix, enabling proactive action before issues arise.

As concrete compositions become more specialized through AI-driven mix designs, ensuring each custom blend cures in ideal conditions becomes even more vital. Smart monitoring closes the loop between material science and on-site execution. It’s a leap in quality assurance that empowers homeowners to invest in concrete features that not only look great the day they’re poured, but stand strong for years to come.

Final words

AI is reshaping concrete construction in ways that benefit both the planet and your property. From smart mix designs to precision curing, these innovations lead to longer-lasting, eco-friendly structures around your home. If you’re planning a concrete project—be it a driveway, patio, or walkway—working with professionals who embrace AI-driven technologies ensures top quality with sustainable results.

Family-owned and operated, Houston’s most trusted commercial and residential concrete experts since 1993. Get a free quote today.

Learn more: https://ccsconcretedriveways.com/#quote

About us

At Cross Construction Services, we specialize in creating durable, aesthetically pleasing driveways that not only enhance the curb appeal of your home but also add significant value to your property. With over three decades of experience in the construction industry, our team in Houston, Texas, is committed to delivering top-quality craftsmanship and unparalleled customer service.